Being a compact top performer, the SR 1 T offers a high hourly capacity and optimal sanitary features. Frozen or directly out of the cooking pot, the Original SR 1 T cuts the best possible cubes and strips from any type of meat.

at one glance

- Serrated knives

- Angled shaft

- Lateral pre-compacting

- Stabilisers for sliced goods

- Tool magazine

- Pressure - sensitive pre-compacting

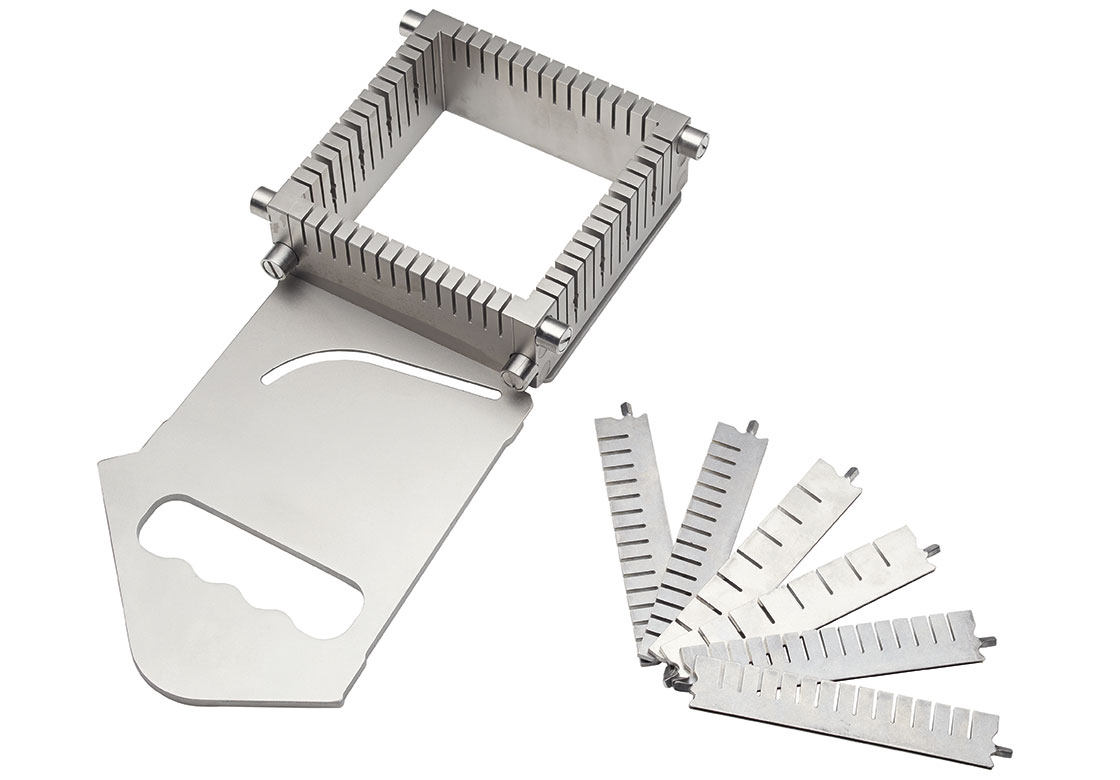

- Multiplex - grid on roller bearings

- Stepless feed adjustment

- Single - foot undercarriage

Further information:

Accessories

Technical specifications

| Machine length | 1.000 - 2.100 mm |

| Machine width | 710 - 1.400 mm |

| Machine height | 1.110 mm |

| Machine weight | 325 kg |

| Connected load | 400 V, 2.1 kW, 16 A |

| Performance | max. 1.500 kg/h |

| Length of shaft | 350 mm |

| Width of shaft | 100 mm |

| Height of shaft | 100 mm |

| Section length | 1 - 32 mm |

| Sections | 160 per minute |

| Cutting temperature | -5°C - +80°C |

| Standard grid sizes | 5, 10, 20, 50 / 6, 12, 24, 50 / 8, 16, 33, 50 |

Back to machine consultants