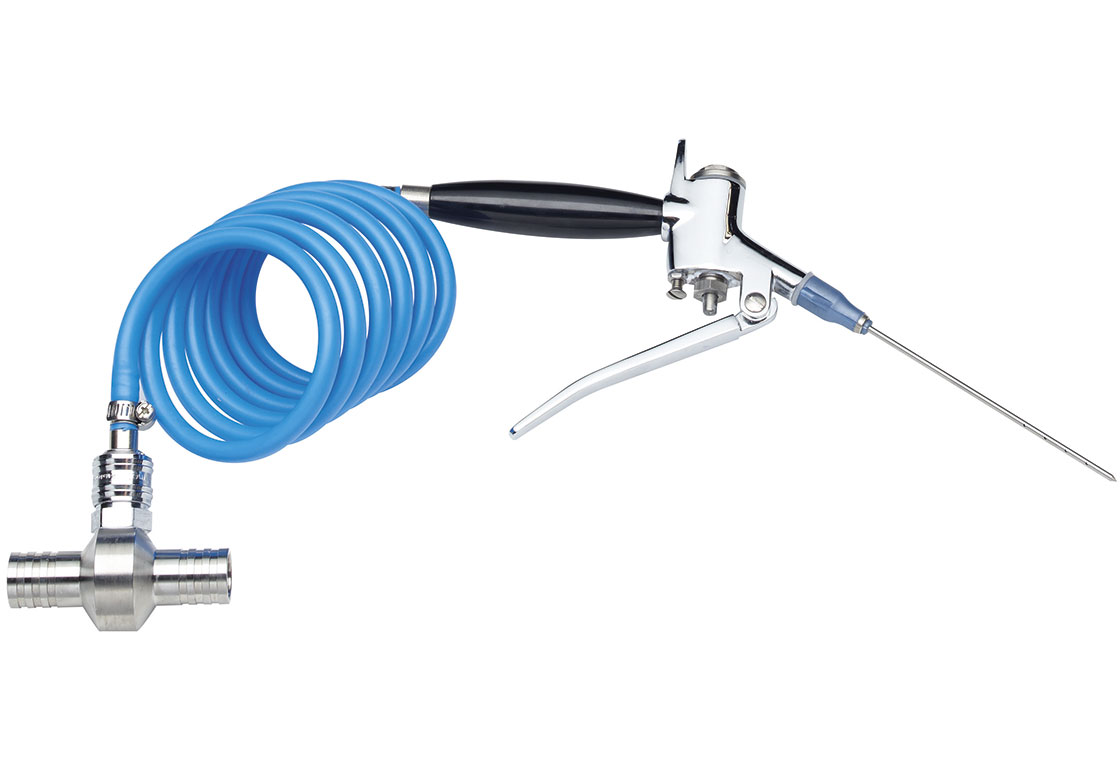

Modern curing technique and timeless steel frame – just the right equipment for perfect results. The Original PR 15 guarantees accurate injection, good operating performance and superior cleaning features.

at one glance

- Stainless steel XXL impeller pump

- Stainless steel belt with grip ridges

- Welded machine construction

- Fold-away workspace

- Automatic belt fastening

Further information:

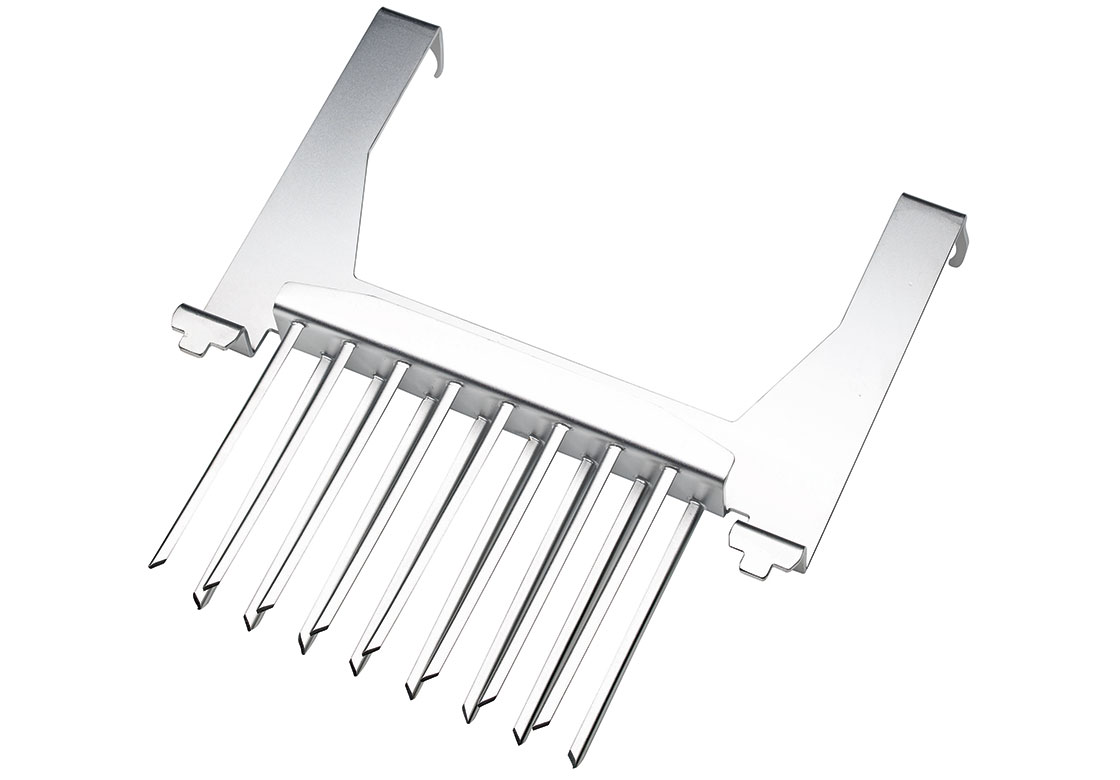

Accessories

Technical specifications

| Machine length | 1.270 - 2.250 mm |

| Machine width | 500 mm |

| Machine height | 1.586 mm |

| Machine weight | 150 kg |

| Connected load | 400 V, 1.8 kW, 16 A |

| Belt advance feed | 25 mm/step |

| Belt width | 270 mm |

| Rows of needles | 2 |

| Feed inlet height | 180 mm |

| Injection volume | 5 - 40 % |

| Injections | 35 per minute |

| Pressure | 0.5 - 4.3 bar |

| Performance | 1.000 kg/h |

Back to machine consultants