The Original MPR 1500 can perform many functions. Counter-rotating mixing offers the option of having one arm rotating faster than the other, or both arms running in synchrony. Large batches achieve unusually uniform consistency, and processing time is significantly shortened. The Original MPR 1500 is the solution to present and future demands in production and food technology.

at one glance

- Tablet control

- 100% container insulation

- Automated lid

- Container swivelling

- Direct cooling system

- Stainless steel vacuum canal, cooled

- Feed system

- Counter - rotating mixing arm

- Quick arm fastening

- Mounting aid (arm)

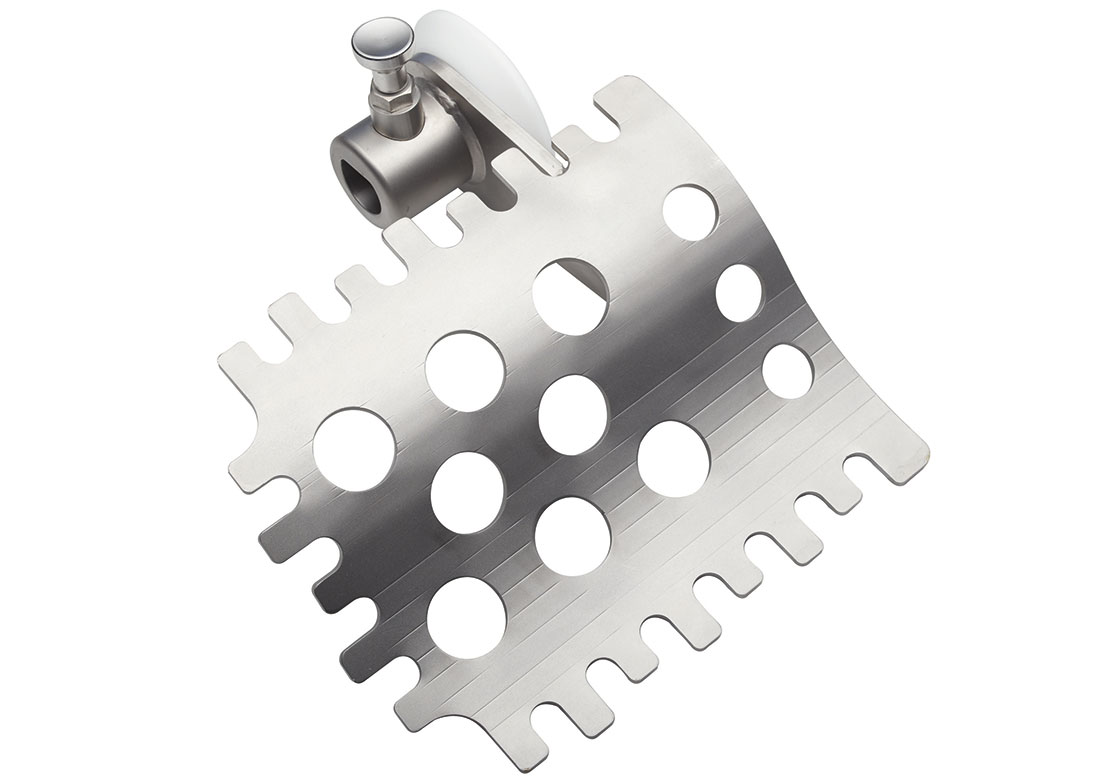

- Scraper, pressure assembling

Further information:

Accessories

Technical specifications

| Machine length | 2.485 - 4.667 mm |

| Machine weight | 2.494 - 4.046 mm |

| Machine height | 2.651 - 3.753 mm |

| Machine weight | 2.920 kg |

| Connected load | 400 V, 14.6 kW, 32 A |

| Filling capacity | 900 l |

| Container size | 1.500 l |

| Coolant | R 452 a |

| Variable arm drive | 0 - 16 Rpm |

| Vacuum system | 0 - 90 % |

Back to machine consultants