With 320 cuts per minute, the fully automatic high-performance machine can process up to 3,500 kg of cut material in one hour. The material can be cut into cubes, strips or rasp in various sizes. In the temperature range from -5°C to +80°C the machine cuts almost any food.

at one glance

- Feed system

- Tablet control

- Pre-filling funnel with chamber loading system

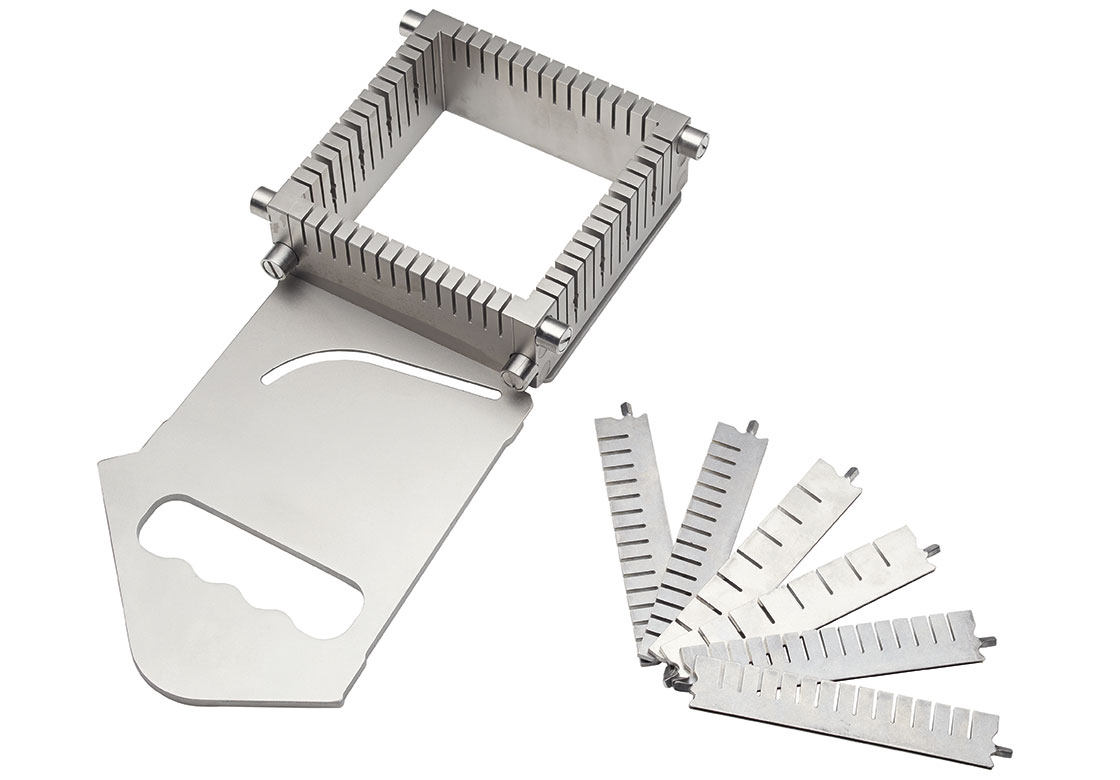

- Serrated knives

- Angled shaft

- Lateral pre-compacting

- Stabilisers for sliced goods

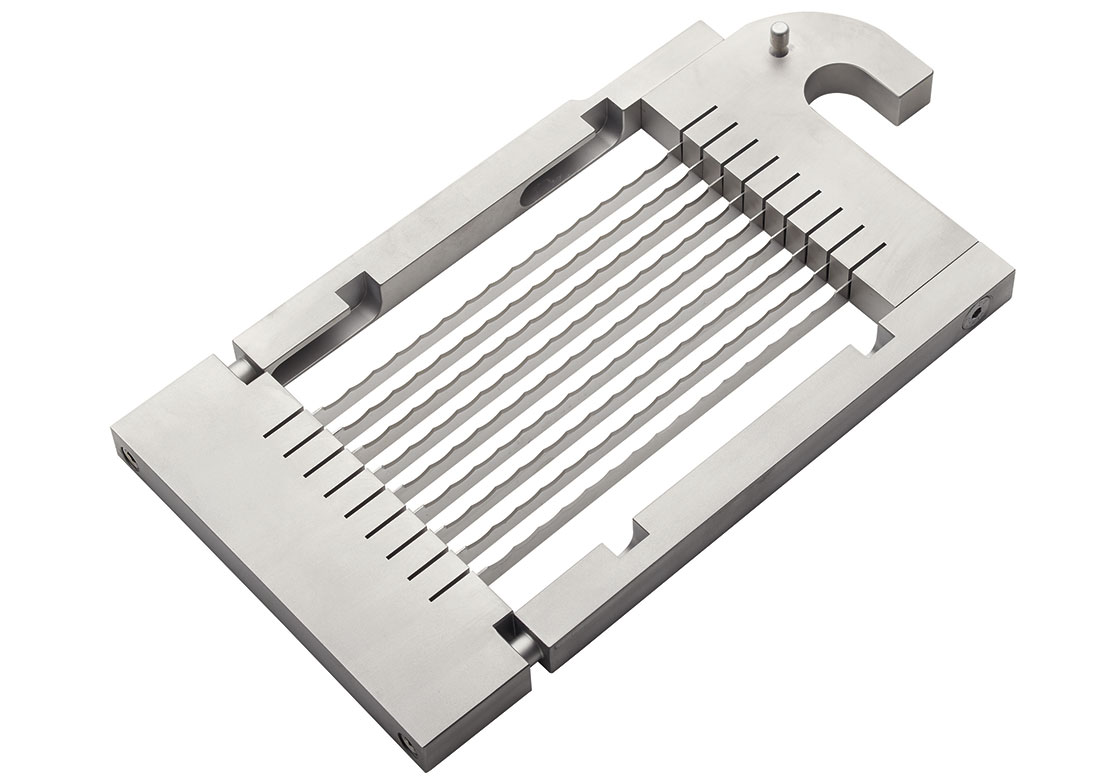

- Multiple-knife-function

- Multiplex - grid on roller bearings

- Pressure - sensitive pre-compacting

- Stepless feed adjustment

- Lift for Eurobins

- Off cut processing system

- Tool magazine

Further information:

Accessories

Technical specifications

| Machine length | 2.800 mm - 3.440 mm |

| Machine width | 1.494 mm - 1.600 mm |

| Machine height | 2.115 mm - 3.145 mm |

| Machine weight | 2.000 kg |

| Connected load | 400 V, 14 kW, 32 A |

| Performance | 3.500 kg/h |

| Length of shaft | 530 mm |

| Width of shaft | 120 mm |

| Height of shaft | 120 mm |

| Sections | 200 pulsating / 320 continuously |

| Section length | 0.5 mm - 32 mm |

| Cutting temperature | -5°C bis +80°C |

| Standard grid sizes | 5, 10, 20, 60 / 6, 12, 24, 60 / 7, 15, 30, 60 |

Back to machine consultants