The semi - automatic Original SR 2 BiTurbo has a high cutting rate and produces up to 3.000 kg of cubes, strips, grated products or portions per hour. This performance is due to the large shaft and fast operating speed as well as (and especially) to time - saving features that prevent idle cuts.

at one glance

- Tablet control

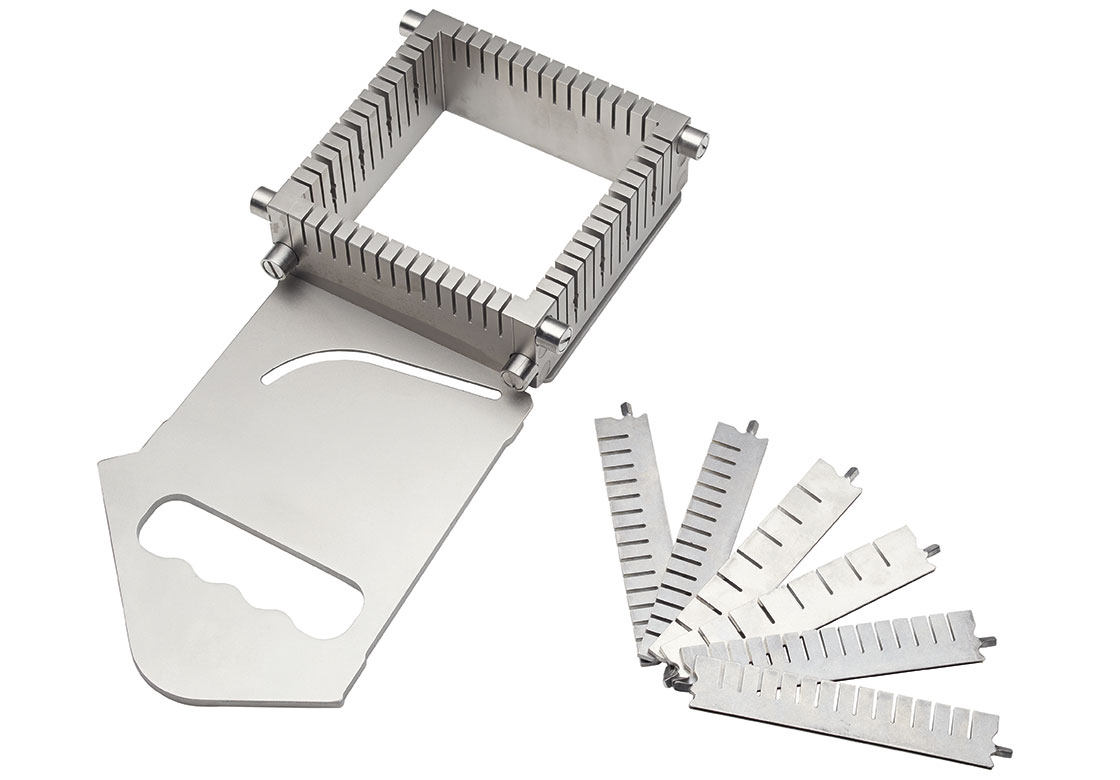

- Serrated knives

- Lateral pre-compacting

- Stabilisers for sliced goods

- Pressure - sensitive pre-compacting

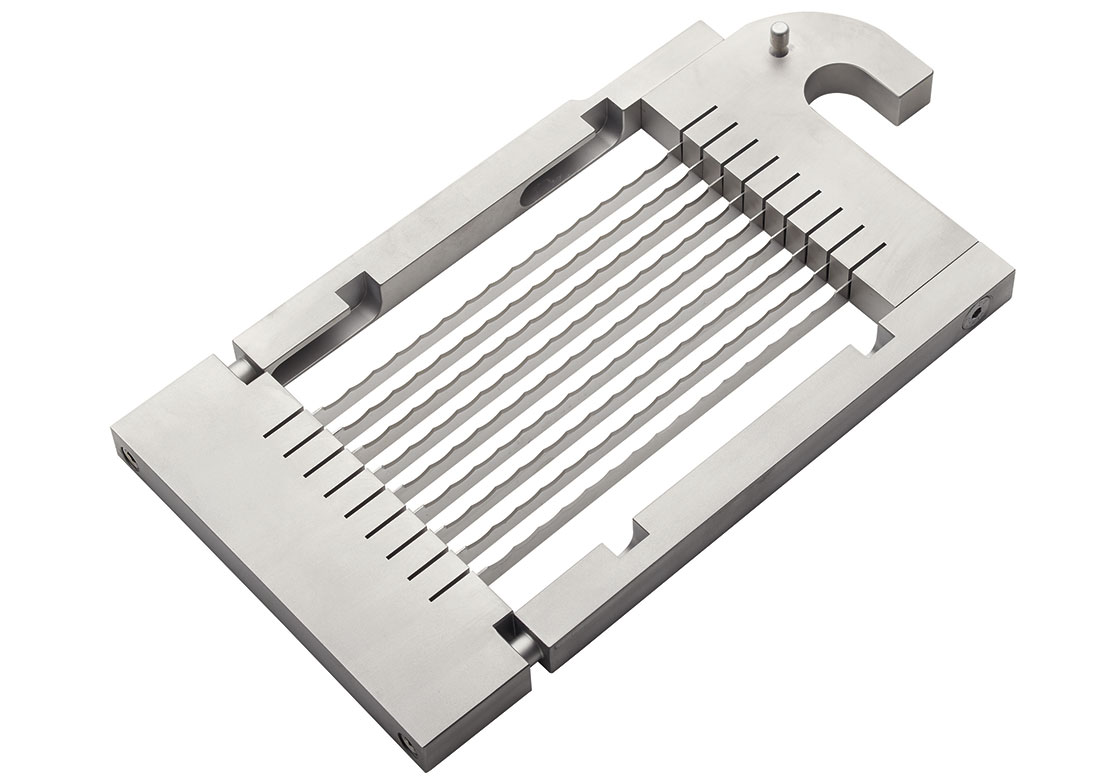

- Multiplex - grid on roller bearings

- Stepless feed adjustment

- Dynamic drive system

- Lift for Eurobins

- Discharging transport belt

Further information:

Accessories

Technical specifications

| Machine length | 1.555 mm |

| Machine width | 1.026 - 1.575 mm |

| Machine height | 1.470 mm |

| Machine weight | 695 kg |

| Connected load | 400 V, 5.3 kW, 16 A |

| Performance | max. 3.000 kg/h |

| Length of shaft | 500 mm |

| Width of shaft | 120 mm |

| Height of shaft | 120 mm |

| Sections | 0 - 300 per minute |

| Section length | 1 - 30 mm |

| Cutting temperature | -5°C - +80°C |

| Standard grid sizes | 5, 10, 20, 60 / 6, 12, 24, 60 / 7, 15, 30, 60 |

Back to machine consultants