Two independent mixing arms, a feed system and a 400 l container can process 300 l of mixing product efficiently, fast and with incredible consistency. In addition, cooling, vacuum treatment and variable arm speeds ensure optimum product yield. The secret of this success lies in its control technology, reflecting decades of experience.

at one glance

- Tablet control

- 100% container insulation

- Automated lid

- Container swivelling

- Direct cooling system

- Stainless steel vacuum canal, cooled

- Feed system

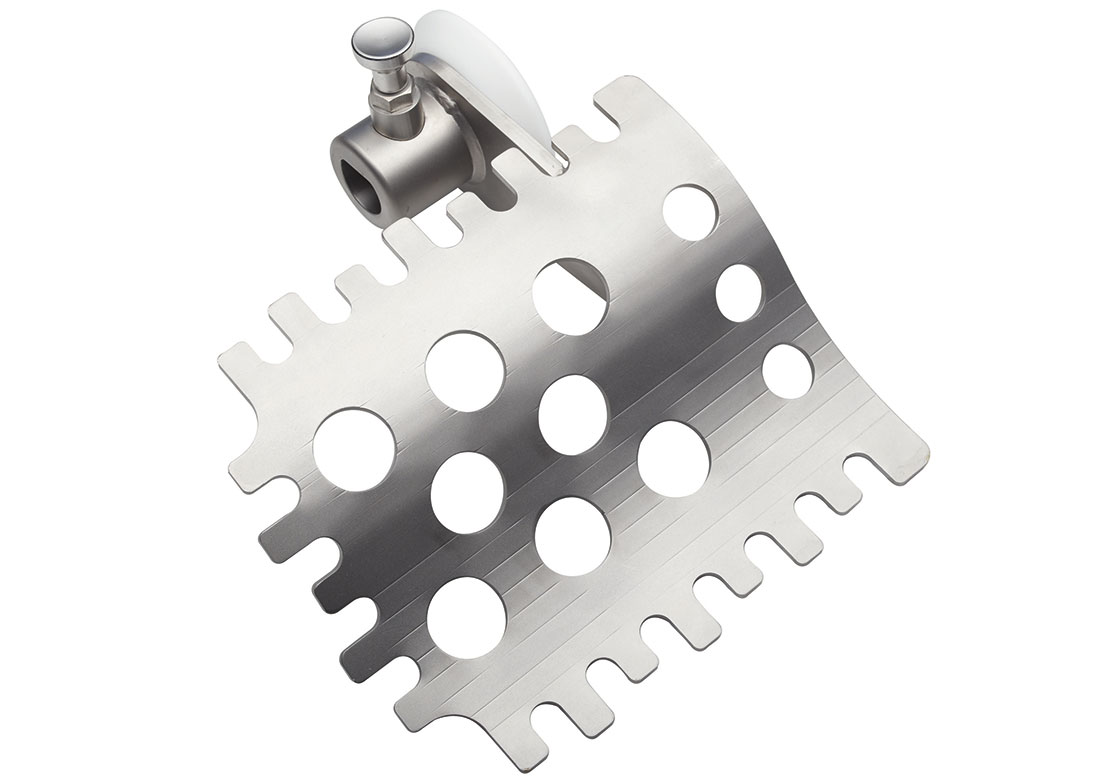

- Counter - rotating mixing arm

- Quick arm fastening

- Scraper, pressure assembling

Further information:

Accessories

Technical specifications

| Machine length | 1.881 - 2.927 mm |

| Machine width | 1.723 - 3.098 mm |

| Machine height | 2.098 - 2.846 mm |

| Machine weight | 1.360 kg |

| Connected load | 400 V, 8.8 kW, 32 A |

| Filling capacity | 300 l |

| Container size | 400 l |

| Coolant | R 452 a |

| Variable arm drive | 0 - 25 Rpm |

| Vacuum system | 0 - 90 % |

Back to machine consultants