At 200 strokes per minute the Original KR 1 accurately cuts and portions chops, roulades, cordon bleu and schnitzel. Even thick - boned meat can be cut into slices of between 1 and 32 mm thickness.

at one glance

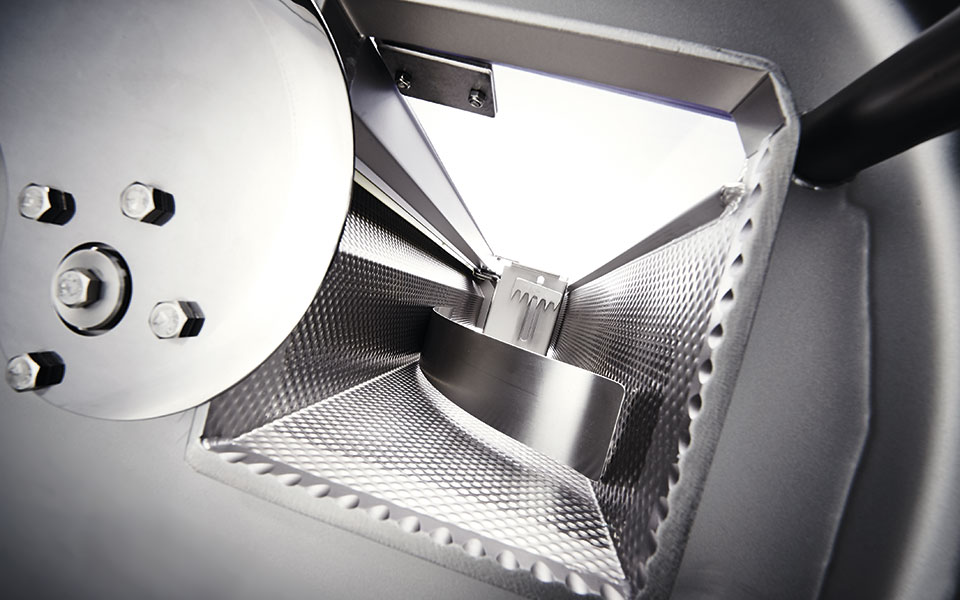

- Angled shaft

- Lateral pre-compacting

- Mechanical drive system

Further information:

Technical specifications

| Machine length | 1.860 - 2.912 mm |

| Machine width | 830 mm |

| Machine height | 1.230 mm |

| Machine weight | 240 kg |

| Connected load | 400 V, 2.7 kW, 16 A |

| Length of shaft | 750 mm |

| Width of shaft | 210 mm |

| Height of shaft | 230 mm |

| Section length | 1 - 32 mm |

| Sections | 200 per minute |

| Cutting temperature | -4°C - +80°C |

Back to machine consultants