In the process of upgrading the curing injector, we have used more than 35 years of experience to good use. No technological advantage has gone unexplored. The result is the Original IR 17 – a more precise, more powerful and more efficient machine with 17 needles.

at one glance

- Variable operating speeds

- Single - needle control

- Stainless steel immersion / rotary pump

- Stainless steel belt

- Welded machine construction

- Standard trolley clearance

- Fold-away workspace

Further information:

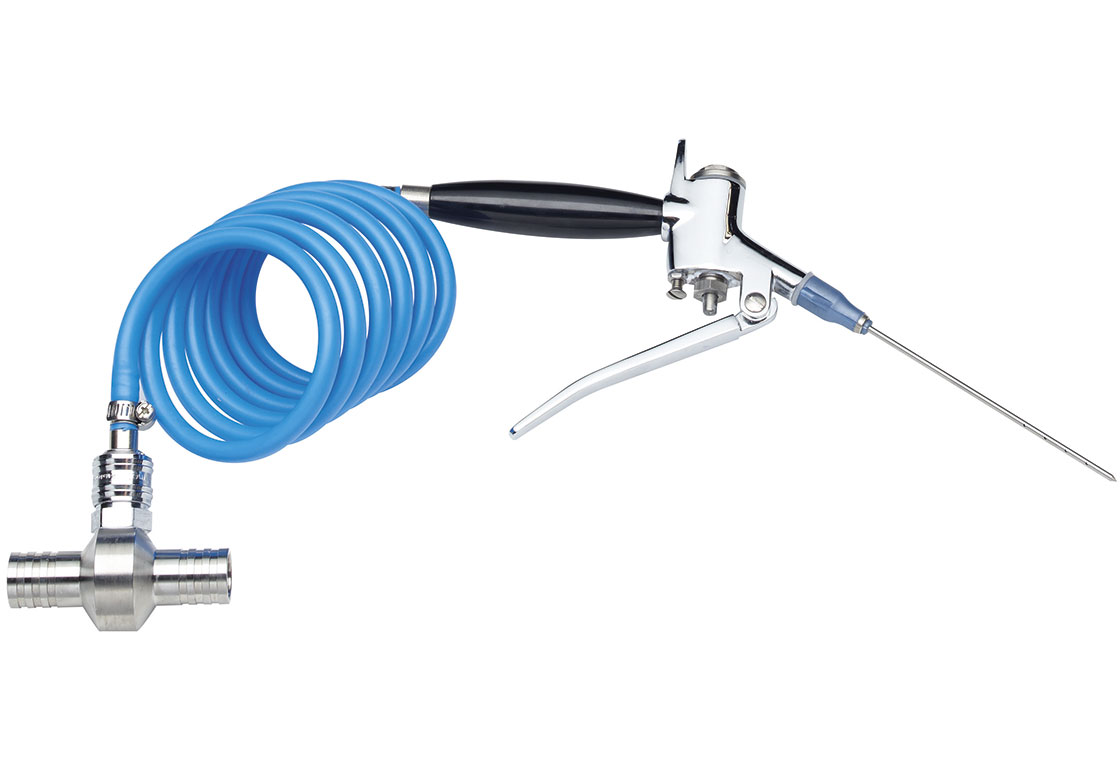

Accessories

Technical specifications

| Machine length | 1.026 mm - 1.855 mm |

| Machine width | 681 mm |

| Machine height | 1.850 mm |

| Machine weight | 250 kg |

| Connected load | 400 V, 5.3 kW, 16 A |

| Performance | 1.000 kg/h |

| Injections | 22 / 44 per minute |

| Belt width | 265 mm |

| Rows of needles | 2 |

| Feed inlet height | 280 mm |

| Injection volume | 3 - 60 % |

| Pressure | 0.3 - 4.2 bar |

| Belt advance feed | 20 mm |

Back to machine consultants